Model | APC2020 |

Angle size processed | ∠63×4 ~ ∠200×20 (Q235-A or 16Mn) mm |

Max. workpiece length | 14 m |

Max. length of finished angle | 12 |

Max. punching(Dia.*thickness) | Φ26 *20mm |

Norminal punching force | 1100KN |

Nominal Marking force | 1030 kN |

Nominal cutting Force | 1800KN |

No. of punch on each side | 3 |

No. of character group | 4 |

No. of character per each group | 18 |

Character size | 14*10*19mm |

Range of stadia | 20~170mm (stepless) |

Max. feeding speed | 40 m/min |

Punching rate | About 1000 hole/hour |

No. of CNC axis | 3 |

Cutting mode | double-blade cutting |

Machine overall size | 32*7*2.2 m |

Machine total power | 43.5 kw |

Machine weight | Approx. 17 t |

Name | Brand | Country | |

1 | AC servo motor | Panasonic | Japan |

2 | Positioning module | Yokogawa | Japan |

3 | Programmable controller | Yokogawa | Japan |

4 | Contactor | TE | France |

5 | Motor switch | TE | France |

6 | Support chain | Igus/Cps | Germany/Korea |

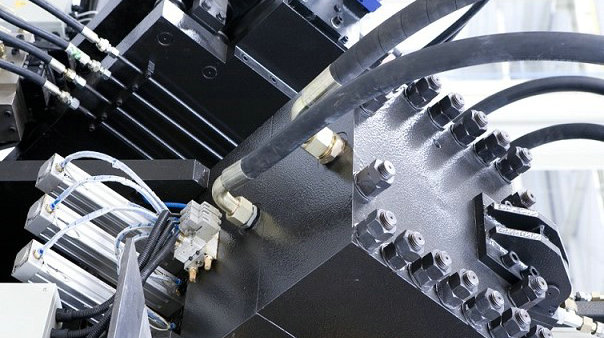

7 | Unloading valve | Atos/Yuken | Italy/Taiwan |

8 | Relief valve | Atos/Yuken | Italy/Taiwan |

9 | Electrohydraulic reversing valve | Atos/Yuken | Italy/Taiwan |

10 | Electromagnetic reversing valve | Atos/Yuken | Italy/Taiwan |

11 | Check valve | Atos/Yuken | Italy/Taiwan |

12 | Valve | Smc/Ckd | Japan |

13 | Valve plate | Smc/ Ckd | Japan |

14 | Valve | Airtac | Taiwan |

15 | Cylinder | Smc/ Ckd | Japan |

16 | FRL | Smc/ Ckd | Japan |

Serial No. | Code | Name | Quantity | Notes |

1 | BL20.6-14 | The upper blade | 2 | Including the blade installed in the machine |

2 | BL20.6-12A | The Short Nether Blade | 4 | Including the blade installed in the machine |

3 | BL20.6-13A | The Long Nether Blade | 4 | Including the blade installed in the machine |

4 | APM2020.5-35 | Die carrier | 7 | Including the die carrier installed in the machine |

5 | APM2020.5-36 | Poles of the Punches | 7 | Including the poles installed in the machine |

6 | BL20.5-32 | Nuts of the Punches | 7 | Including the nuts installed in the machine |

7 | APM2020.5-37 | Punches for test run | 12 | Including the punches installed in the machine |

8 | APM2020.5-38 | Female die for test run | 24 | Including the female die installed in the machine |

9 | APM2020.2-28 | The upper claw | 2 | Including the claw installed in the machine |

10 | APM2020.2-32 | Spring | 2 | Including the spring installed in the machine |

11 | PP103A.2-21 | The Wrench for Tightening the Punches | 1 | |

12 | Common tools (including:full set of inner hexangular wrench, 500, 300, 150MM adjustable wrench, two solid wrench, a set of screwdriver) | 1set | ||

13 | Standby paint | 2 kegs | 1 keg for main color and 1 keg for warning color | |

14 | Tools for charging | 1 | ||

15 | The Drawing for Fragile Parts | 2 volume | ||

16 | The Drawing for Maintenance | 2 volume | ||

17 | Instruction(mechanical part) | 2 volume | ||

18 | Instruction(electric part) | 2 volume | ||

19 | Instruction(Hydraulic part) | 2 volume | ||

20 | Quality Certificate | 1 volume | ||

21 | Packing List | 1 volume |